mattermorphosis

[cornell university, spring 2020]

The aesthetic and conceptual qualities are informed by the exploration of pulling plastic through the method of extrusion. A 3D printed bioplastic cube served as a concept model in the development of a workshop in whcih biodegradable bioplastic is manufactured from corn into 3D printed bricks. The brick-plastic material is filled with corn seeds that will plant themselves when the bricks dissolve. Situated in a site rationalized by a grid, the structure requires all aspects of the corn crop as the main source of material, including parts that are typically discarded in the agriculture process. The structure is meant to move across the cornfield on this grid in order to propagate and rejuvenate cropland.

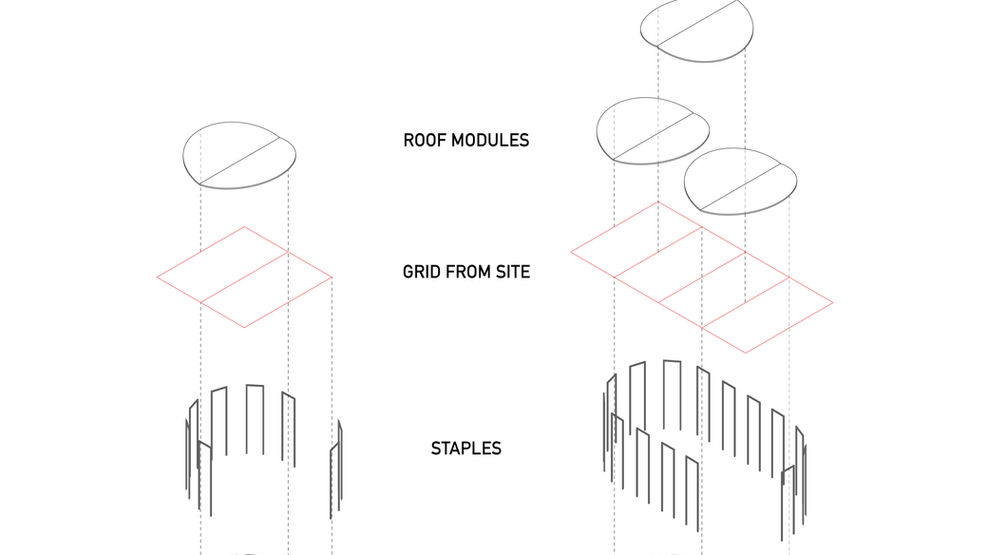

From the material study of the cube, opaque plastic is used for the structural bricks that form shelves, tables, and handholds, and translucent bricks form the rest of the structure to provide light. The 3d-printed bricks merge internal and external formations with the overall wall structure to allow for a kit-of-parts method of manufacture. The bricks are supported by metal staples that form a substructure so that the building can change predictably over time.

The project functions at three scales to streamline the construction process: the site, the building, and the brick. All three levels give an intrinsic blueprint to organize the workman’s construction and movement across the field.

[drawings]